Intelligent vacuum carburizing and quenching technology

Home > English > News >

OneTechnical name: Intelligent vacuum carburizing and quenching technology

TwoTechnology field and scope of application: enterprises with general requirements for carburizing heat treatment process in the machinery industry

ThreeEnergy consumption and carbon emissions related to the technology

In 2012, China's total heat treatment production was about 20 million tons, of which carburizing treatment accounted for about 1/8, about 2.5 million tons. The main equipment for carburizing treatment includes well type furnace, box type multi-purpose furnace and vacuum carburizing furnace, in which well type carburizing is about 1.25 million tons, box type carburizing is about 1,237,500 tons, and vacuum carburizing is about 12,500 tons. The power consumption of the well type furnace is the highest, the box type multi-purpose furnace is the second, and the vacuum carburizing furnace is the lowest. According to JB/T50182-1999 "Energy consumption classification of box type multi-purpose heat treatment furnace", the first-class comparable unit consumption index of box-type multi-purpose road is bk≤440kWh/t, and the comparable unit consumption of vacuum carburizing furnace is bk=265kWh/ t. The energy saving of the vacuum carburizing furnace relative to the box type multi-purpose furnace is about 61kgce/t, and the emission reduction is about 161kgCO2/t. At present, the application of this technology can achieve energy savings of 10,000 tce / a, CO2 emission reduction of about 30,000 t / a.

FourTechnical content

1.Technical principle:Vacuum carburizing is a vacuum heat treatment process. Since carburization is carried out in a vacuum environment, the carbon potential can be precisely controlled, and the surface of the workpiece is clean, which is favorable for adsorption and diffusion of carbon atoms, and achieves high-temperature carburization speed. Compared with ordinary carburizing, the carburizing time can be shortened by more than 50%, and the electric energy is greatly saved. In the vacuum environment, it is also possible to effectively prevent intergranular oxidation of the oxidizing gas and the alloy elements on the surface of the workpiece, improve the wear resistance and fatigue performance of the workpiece, and at the same time achieve carburization of the inner surface of the pores and the like, so that the entire batch of workpieces is evenly obtained. Consistent surface carbon concentration and carburized layer thickness.

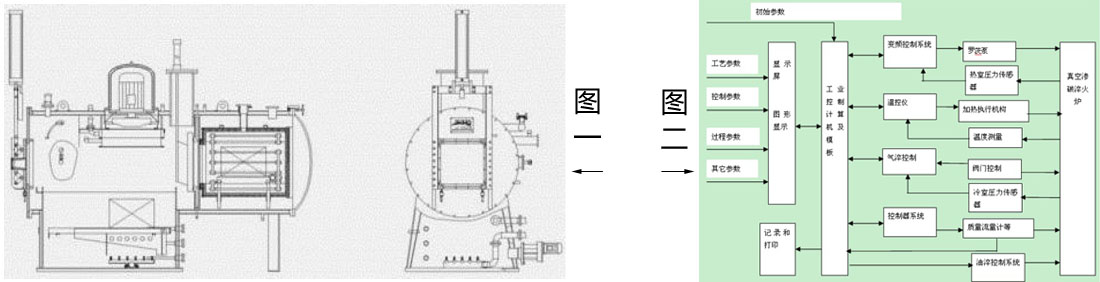

The intelligent vacuum carburizing quenching furnace uses computer control system to accurately control the four important parameters of temperature, time, carburizing gas flow and pressure, to ensure the temperature uniformity and uniformity of the furnace, and to obtain the minimum seepage of the carburized workpiece. Layer depth error and reasonable crystal phase distribution. At the same time, under the control of the computer, the carburizing agent can enter the furnace with a multi-channel multi-nozzle at a precise flow rate, and the distribution surface is wide and uniform, and the cracking and carburizing reaction occurs sufficiently, and excessive free carbon is not generated, thereby effectively reducing the carbon black to the furnace body. Pollution.

2. Key technologies:①atmosphere flow control technology; ②Technology to reduce carbon black pollution.

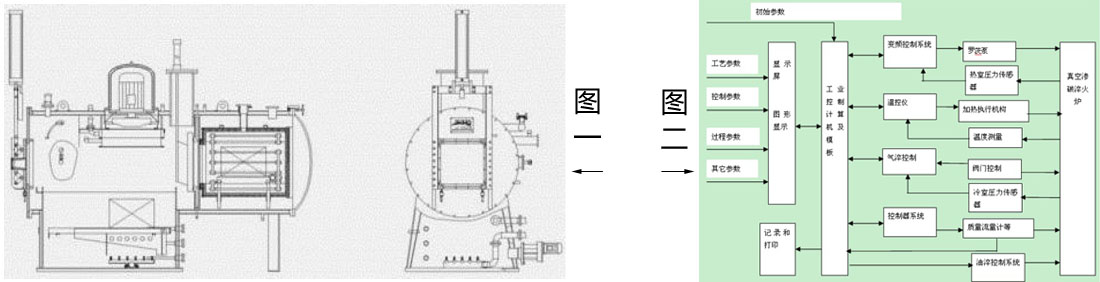

3. Process flow:Workpiece → cleaning → generation or preparation process → furnace → vacuum carburizing → quenching or cooling. The structure diagram and the schematic diagram of the automatic control system are shown in Figure 1 and Figure 2, respectively.

FiveMain Specifications

-

1. Power consumption: 265kWh/t

-

2. Maximum working temperature: 1300oC;

-

3. Furnace temperature uniformity: ≤ ± 5oC;

-

4. Ultimate vacuum: ≤ 4 × 10-1Pa;

-

5. Pressure rise rate: ≤ 0.65 Pa / h;

-

6. Quenching transfer time: ≤ 25S;

-

7. Gas pressure: ≤ 12bar;

-

8. Hardened layer depth deviation: ≤ ± 0.1mm.

SixTechnical appraisal, award status and application status

The technology passed the inspection of the National Electric Furnace Quality Supervision and Inspection Center in 2010, and passed the appraisal organized by the China Heat Treatment Industry Association in 2012, and obtained a number of national utility model patents. At present, more than 10 intelligent vacuum carburizing quenching furnaces have been applied in the domestic machinery industry.

SevenPromotion prospects and energy saving potential

At present, the proportion of vacuum carburizing in the domestic heat treatment industry accounts for a small market, which is less than 1%. With the rapid development of the domestic market, the annual demand for vacuum carburizing quenching furnace is about 30 units. It is estimated that in the next five years, the technology is expected to be promoted at a rate of 15%, and the annual energy-saving capacity can be 100,000 tce, and the annual emission reduction potential is 260,000 tCO2.