Quality advantage: The cleansing advantages of natural gas can minimize the impact of emissions on the environment. With this advantage, the furnace exhaust can be discharged directly into the plant without affecting the production environment of the workshop.

Quality advantage: The cleansing advantages of natural gas can minimize the impact of emissions on the environment. With this advantage, the furnace exhaust can be discharged directly into the plant without affecting the production environment of the workshop.

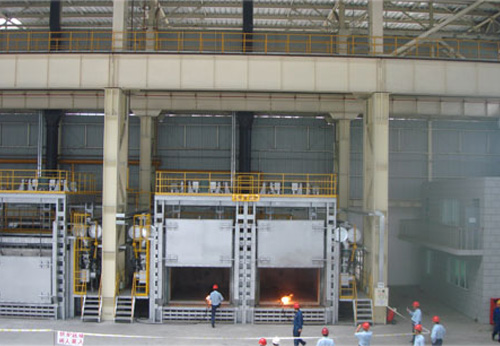

Advantages of gas-fired heating furnace for forged parts:

- Quality advantage: The cleansing advantages of natural gas can minimize the impact of emissions on the environment. With this advantage, the furnace exhaust can be discharged directly into the plant without affecting the production environment of the workshop.

- Structural advantages: The gas-fired heating furnace for forged parts can operate without relying on the pumping force of the chimney, and only needs an iron chimney that is about 2 meters above the top of the furnace. In this way, the flue and chimney investment can be saved, and the furnace can be installed without being restricted by the position of the flue, and the process flow arrangement is more reasonable.

- Energy-saving advantages: The short chimney of the natural gas heating furnace roof is easily made into a heat exchanger, which preheats the combustion air required for combustion, thereby improving the thermal efficiency.

Burning characteristics:

- For small and medium-sized gas-fired heating furnace for forged parts, natural gas burners are usually mounted on the top.

- For medium and large heating furnaces, the burners are mounted on both sides. In order to make the furnace temperature uniform, a high speed burner should be used. The burners used for forging heating generally do not use fully automatic mechatronic burners, but use automatic split burners, which is beneficial to obtain high-speed flames and flexible process control.

Jiangsu Jiuding Industrial Furnace Technology Co., Ltd. is a young enterprise with unique ideas on the design and manufacture of industrial furnaces and heat treatment furnaces.

To provide you with equipment design, process design, suitable for your heat treatment equipment purchase plan, according to your requirement.